reducing waste with our on-demand business model

Our on-demand business model lets us order only what customers want, when they want it. For each item, we order the production of only a small initial batch of 100 to 200 pieces and respond directly to customer demand to determine future orders from our suppliers. This allows us to consistently achieve average unsold inventory in the low single digits, far below the industry average, which means less resource waste right from the beginning.

Leveraging Technology to Conserve Resources

We are continuously optimizing efficiency along the value chain to conserve resources – water, energy and raw materials — minimizing consumption and waste to use only what is needed, not more. We do this using the following techniques:

- We work with and encourage our suppliers to adopt practices to consume less water through new manufacturing technology and production processes. Many of our suppliers also use closed-loop water treatment and reuse processes that help conserve water.

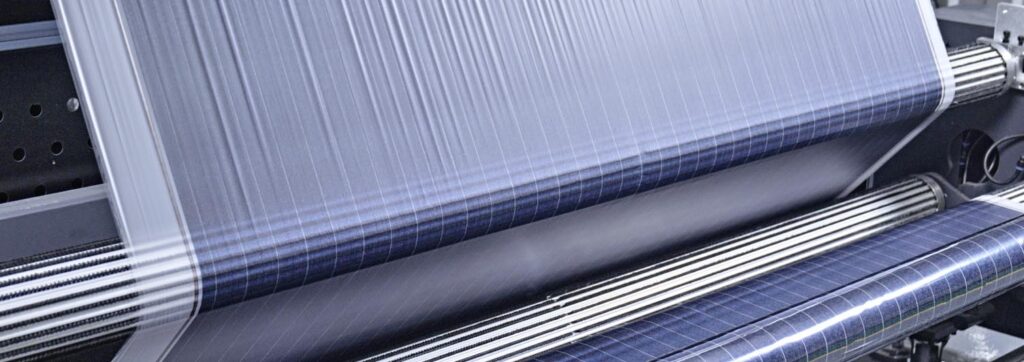

- In December 2018, we launched our Digital Transfer Printing initiative, a zero-water waste printing method verified by Bureau Veritas. We have converted over 50% of directly sourced prints to digital thermal transfer printing.

- SHEIN is also working with suppliers to increase adoption of cool transfer denim printing technology. This digital small-batch production method can achieve similar effects to traditional dyeing and distressing methods while greatly reducing water consumption.

These techniques perfectly support SHEIN’s small-batch production process, cutting down on inventory waste and conserving resources from the start.